Why choose us?

a. With experiences over 10 years.

b. Strict inspection and high quality with reasonable price.

c. OEM and ODM service provided.

d. Delivery time is short and on-time.

We can give you the direct factory price without broker. Our products are cost-effective with 100% QC quality assurance before shipment. We have our own design team and advanced high-precision machines and testing equipment.

What kinds of products you supply?

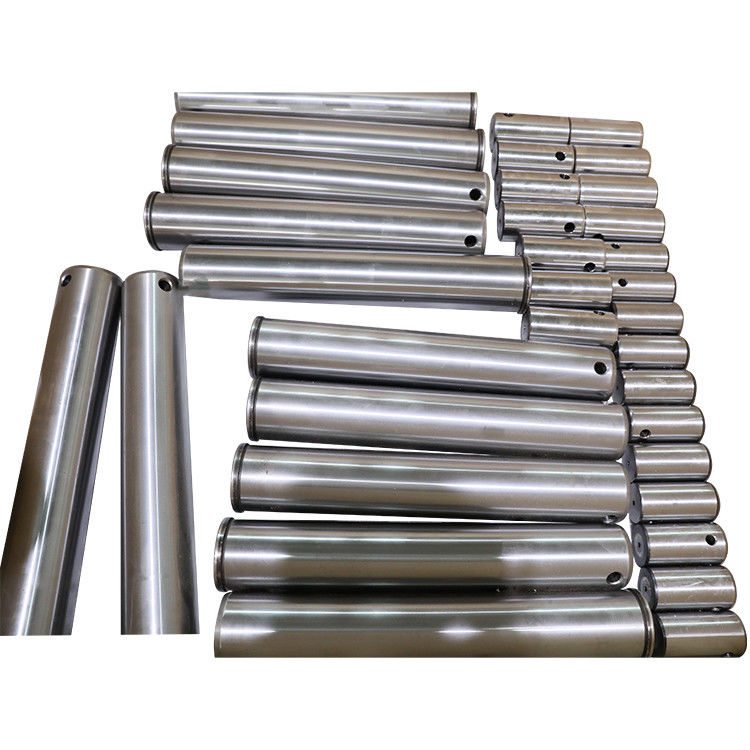

Main products are bushing,pin,,shim washers,etc, as per customers' drawings or samples.

Can I have a sample order or trail order?

Yes, it is available to check quality first. Mixed samples are also acceptable.

What about the lead time or delivery time?

In stock: 1-3 days. Usually in 24 hours.

Out of stock: 3-7 days for samples, 3-4 weeks for mass production. It's according to your quantity, and we will let you know when we quote.

What is your payment method?

We accept T/T, Western Union, L/C, credit card or via ALIBABA Assurance order.

Do you support special customized product (OEM or ODM)?

Of course, our company has experienced and professional engineers and possess a number of testing equipment. It can meet all customized requirements of customers while ensuring product quality.

What's your MOQ?

We will indicate the MOQ for each item in the quotation sheet.Normally, our minimum order is USD5000, one 20'

full container load and LCL container (less than a container load) can be acceptable.We accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

What's about the quality of you products?

We are specialized in high quality products and make products according to drawings and samples strictly to meet your 100% satisfaction.

Are you a trader or a manufacturer?

We are a factory-based and trade integration company, always professional and reliable. Our factory is located in Shandong Liaocheng, and our sales department is in the City centre of Jinan. The distance is 150Km, 1.5

hours. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.

How can I be sure the part will fit my machine?

Pls try to give us as much of the following info as possible:

- Correct model number

- Part number

- Machine serial number

- Any numbers on the part itself

- Any measurements you are able to get.

Or just give us drawing.

What about your Quality Control?

We produce as per the confirmed technology or drawings for each order for our customers. We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully,monitor every production process until packing is complete, to ensure products safety into the container.

May I have my order working schedule?

Yes, we will send working schedule of your order each week. We will inspect and test all merchandise in case of damaging and missing parts before shipment.The detailed inspection pictures of the order will be sent to you for your confirmation before delivery.

Do you like to serve the customers only with small orders?

We are always glad to grow up together with all our customers whatever big or small. We hope our customers become stronger and stronger to be with us.

What's package of your products?

We can provide standard export package with wooden box or carton, of course, customized package according your requirement is available.

What's the terms of the trasaction?

Usually we adopt EXW or FOB, and FCA, FAS, CIF, CIP, DDP and other method is available as your requirements.

Do you provide free samples?

Yes, usually we provide free samples for testing under the condition of gurantee deposit and freight paid by customer, but can be returned after the order is placed.

How long can I get some samples for checking and what about the price?

Normally samples will be done within 1-2 days (automatic machining parts) or 3-5 day (cnc machining parts). The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your order quantity is good.

When inspecting steel bushing, what should we need to consider?

1. Whether the surface treatment is smooth

2. Accuracy

3. Hardness

Your product certifications?

ISO 9001:2008, ISO14001, RoHS

What is the warranty for our products?

One year from the date of leaving the factory, our company is solely responsible for after-sales service for product quality problems that are not caused by improper use, improper storage or human reasons.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!